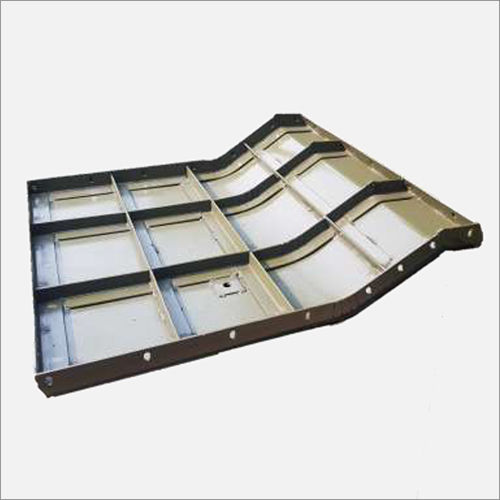

Haunch Shuttering Plates

Product Details:

- Product Type Haunch Shuttering Plates

- Material Mild Steel or MS plate

- Usage Formwork for concrete construction

- Application Bridge girders, columns, beams, and industrial structures

- Size Customized/Standard sizes (commonly 600mm x 900mm or as per requirement)

- Weight Approx. 20-40 kg/piece (varies by dimension and thickness)

- Color Grey or as per surface finish

- Click to view more

X

Haunch Shuttering Plates Product Specifications

- Mild Steel or MS plate

- Grey or as per surface finish

- Min 250 MPa (standard mild steel grade)

- Approx. 20-40 kg/piece (varies by dimension and thickness)

- Formwork for concrete construction

- Haunch Shuttering Plates

- High load bearing for construction operations

- Bridge girders, columns, beams, and industrial structures

- Customized/Standard sizes (commonly 600mm x 900mm or as per requirement)

- Reusable, Durable, Precise shape, Corrosion resistant

- Anti-corrosive, smooth finish for easy de-shuttering

- Can be provided with welding lugs or clamp holes

- Usually ranges between 3mm to 8mm

- Designed for multiple reuses in construction projects

- Precision cut, welded and fabricated

- Painted, galvanized or untreated as per order

- Smooth or beveled edges for seamless assembly

- Rectangular/Haunch/Custom geometric shapes

Product Description

The high-quality haunch shuttering plates used in shuttering come in durable frame construction so as to deliver for lasting procedure. Additionally, these connections find applications in areas in need of high moment transfer as well as provision boosting effective depth of sections. Some of the appreciable features of these shuttering plates enable them to work as the superior adjustment supports. These are suitable for uses on single storey sheds, which allows for elementary connection support. Haunch shuttering plates can also be made accessible in assorted specifications.

Precision Engineering for Reliable Formwork

Each Haunch Shuttering Plate is fabricated through advanced precision cutting and welding, ensuring accurate dimensions and consistent quality. Smooth or beveled edges contribute to seamless assembly, reducing installation time and improving construction efficiency. The customizable nature of these plates addresses diverse architectural needs, making them an ideal choice for demanding projects.

Superior Surface Treatment and Long-Lasting Protection

Choose from painted, galvanized, or untreated finishes to suit your project's specific requirements. Anti-corrosive coatings, paired with a smooth finish, guarantee longevity and multiple reuses in harsh construction environments. These treatments enhance resistance against moisture and abrasion, safeguarding the integrity of both the formwork and finished concrete.

Versatile Applications Across Structural Projects

Haunch Shuttering Plates support a wide range of concrete forming needs, such as bridge girders, columns, beams, and various industrial structures. Their high load-bearing capacity, precise shape, and corrosion resistance permit extensive use both in routine and complex construction operations. Accessories like welding lugs and clamp holes further facilitate versatile integration with standard and custom formwork systems.

FAQ's of Haunch Shuttering Plates:

Q: How are Haunch Shuttering Plates fabricated for construction projects?

A: Haunch Shuttering Plates are manufactured using precision cutting, welding, and fabrication processes. This ensures each plate meets the exacting standards required for concrete formwork, resulting in accurate shapes and smooth or beveled edges for easy assembly.Q: What surface treatments are available for these shuttering plates?

A: The plates can be supplied painted, galvanized, or untreated, based on project requirements. Painted and galvanized finishes offer enhanced corrosion resistance, prolonging service life and enabling multiple reuses in varying construction environments.Q: When should Haunch Shuttering Plates be used in concrete construction?

A: These plates are ideal for formwork in demanding applications like bridge girders, columns, beams, and industrial structural elements. Their robust design and anti-corrosive finish make them suitable whenever durable, reusable, and precisely shaped formwork is needed.Q: Where can customized or standard Haunch Shuttering Plates be ordered?

A: You can order both standard sizes (commonly 600mm x 900mm) and custom dimensions directly from manufacturers and suppliers based in India, ensuring tailored solutions for specific project needs.Q: What are the key benefits of using Haunch Shuttering Plates?

A: Key benefits include high load-bearing capacity, reusable and durable construction, anti-corrosive finishes, and precise geometric shapes. These features lead to smoother concrete surfaces, easier de-shuttering, and overall improvements in construction efficiency.Q: How are accessories like welding lugs or clamp holes used with these plates?

A: Welding lugs and clamp holes are provided for secure attachment and integration within broader formwork systems. They help ensure stable assembly and facilitate quick installation, adapting easily to a variety of construction requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Shuttering Range' category

We supply our products in Odisha, Jharkhand, Bihar, North Eastern States, West Bengal, Andaman and Nicobar Islands, Andhra Pradesh, Arunachal Pradesh, Assam, Manipur, Meghalaya, Nepal and Bhutan.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese